Gesture Recognition in Ultra-Range Distance for HRI

AllSight: A Low-Cost Tactile Sensor with Zero-Shot Learning Capability

Haptic-based and SE(3)-aware Object Insertion using Compliant Hands

Intuitive intention recognition for collaborating with robots

We are developing a low-cost device worn on the human arm which, using force sensors, captures radial force distributions through expansion and contraction of the musculoskeletal system. Using machine learning techniques, the measurement of force distributions enables analyzing the state of the human arm during natural motion. Consequently, a robotic arm will be able to recognize the intent of the human, for instance, during the manipulation of an object, and act to assist in a shared task. Such technology would be able to assist the elderly and disabled with daily life activities, assist workers in a plant in hazardous tasks, and participate in medical procedures. Future robots would autonomously work side by side with humans in complex tasks. Such robots will increase productivity and, more important, improve our quality of life.

Watch Nadav Kahanowich presents his work at ICRA 2021:

Dual-arm manipulation of elastic wires

We investigate approaches for accurate dual arm manipulation for elastic wires. While the configuration space of a rigid body is given by its pose, the configuration space of a deformable elastic rod is given by its pose and shape. This makes the planning problem of dual-arm manipulation of such elastic rods more complex. However, the configuration space of an elastic rod, i.e., the set of all equilibrium configurations, was shown in previous results to be a six-dimensional smooth manifold. This discovery enables the use of standard sampling-based motion planners to easily plan the manipulation of such rods. We incorporate advanced methods of motion planning, machine learning and control to plan and deploy successful manipulations.

Check-out Itamar Mishani’s work on shape estimation and control of elastic wires, published at IEEE RA-L and presented at at ICRA 2022:

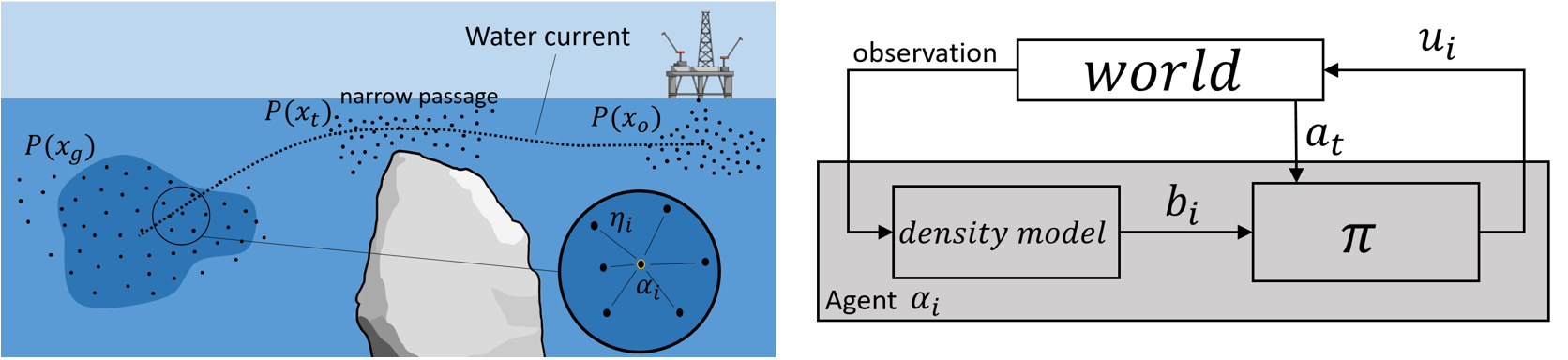

Underwater Robotic Swarms for Pollutants Monitoring and Mapping

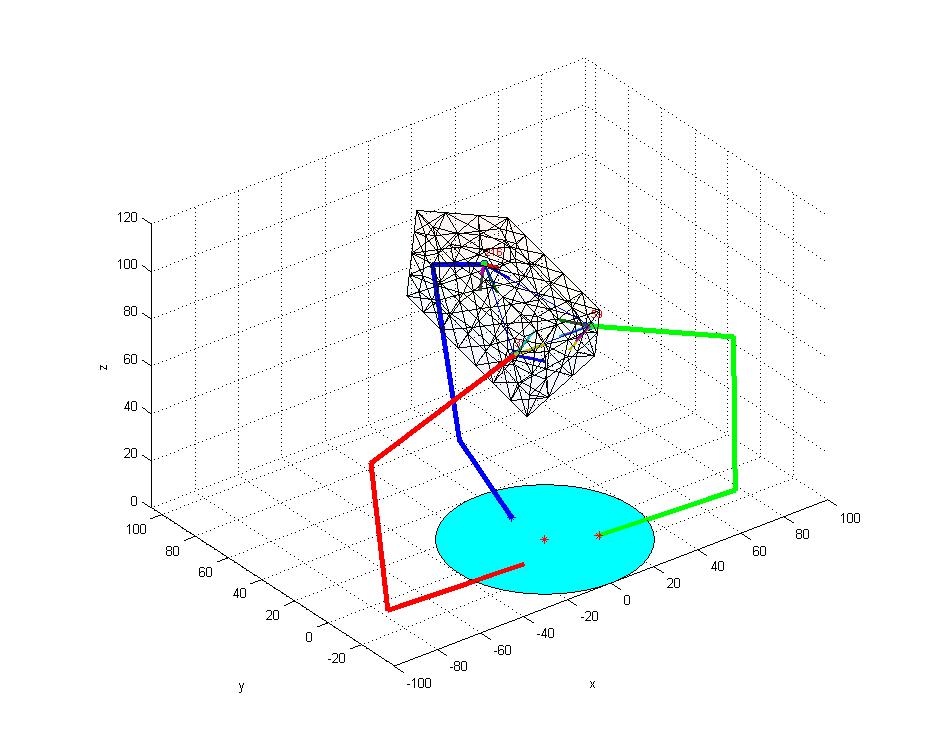

Optimization of a Robotic arm for Palm tree dilution

We build an optimization algorithm for robotic arms in specific tasks such as palm tree dilutions. An arm is optimized based on human experience during these tasks.

In collaboration with Prof. Avital Bechar, Volcani Center.

Past projects

Control and motion planning of adaptive hands

As a part of this project, Dr. Sintov is the creator and maintainer of the RUM dataset.

Work was done in the Pracsys Lab and Robot Learning Lab at Rutgers University in collaboration with Prof. Aaron Dollar’s Grab Lab at Yale University.

Dynamic Regrasping

Dynamic Regrasping by In-Hand Orienting of grasped objects using Non-Dexterous Robotic Grippers

Almost any task on an object requires regrasping of the object prior to performing an intended task by varying between grasp configurations. The human hand uses many methods to perform regrasping manipulations such as in-hand sliding, finger gaiting, juggling, picking and placing, etc. The most complex and inspiring approach is the in-hand orienting dynamic regrasping where an object is released into mid air and regrasped in a different orientation. This manipulation is useful in robotics for rapid manufacturing and reducing the number of robotic arms in production lines. In this work, we present a novel approach for performing in-hand orienting regrasping using computed torque control. To maintain an efficient and low-cost approach, the regrasping is performed using a non-dexterous two-jaw gripper and by utilizing the robotic arm’s dynamics. In addition, we present a novel stochastic motion planning algorithm for performing an optimal manipulation satisfying the kinematic and dynamic constraints. The algorithm optimizes the initial pose of the arm and the control gains.

Statistical analysis shows the probability for the algorithm to find a solution if such exists.

Swing-up regrasping

In this work the swing-up regrasping problem is presented where an object is manipulated using a robotic arm around a point pinched by the arm’s gripper. The aim of the regrasping is to manipulate the object from an initial angle to regrasp it on a new desired angle relative to the gripper. The pinching point functions as a semi-active joint where the gripper is able to apply only frictional torques on the object to resist its motion. We address the problem by proposing a novel approach. The approach incorporates an impulse-momentum method with an LQR-based controller for stabilization on the desired angle. In particular, a sub-optimal Clipped LQR controller is presented to deal with the dissipative semi-active joint. The interaction of these methods with the unique property of the semi-active joint is investigated and analyzed.

CLIBO: Autonomous climbing robot with claws

A novel robot capable of climbing on vertical and rough surfaces, such as stucco walls. Termed CLIBO (claw

inspired robot), the robot can remain in position for a long period of time. Such a capability offers important civilian and military advantages such as surveillance, observation, search and rescue and even for entertainment and games. The robot’s kinematics and motion, is a combination between mimicking a technique commonly used in rock-climbing using four limbs to climb and a method used by cats to climb on trees with their claws. It uses four legs, each with four-degrees-of-freedom

(4-DOF) and specially designed claws attached to each leg that enable it to maneuver itself up the wall and to move in any direction. At the tip of each leg is a gripping device made of 12 fishing hooks and aligned in such a way that each hook can move independently on the wall’s surface. This design has the advantage of not requiring a tail-like structure that would press against the surface to balance its weight. A locomotion algorithm was developed to provide the robot with an autonomous capability for climbing along the pre-designed route. The algorithm takes into account the kinematics of the robot and the contact forces applied on the foot pads. In addition, the design provides the robot with the ability to review its gripping strength in order to achieve and maintain a high degree of reliability in its attachment to the wall.

Common grasp search algorithm

This work addresses the problem of designing a simple End Effector for a robotic arm which is able to grasp a given set of objects. The purpose of this work is to develop an algorithm which will find a configuration and design of a universal end-effector for a set of objects. With given a set of all CAD models of the parts, the idea is to design an end-effector that is universal in the sense of being able to hold a wide set of components for multiple manipulation tasks. The algorithm will be able to characterize the objects geometries and find a configuration for grasping them. An optimal configuration is the one which can stably grasp the object even under the application of external wrench due to the task being done, i.e., we require Force-Closure grasp.

The OCOG (Object COmmon Grasp) algorithm developed, searches for a common grasp over the set of objects. The search algorithm maps all possible grasps for each object which satisfy a quality criterion. The mapped grasps are represented by feature vectors in a high-dimensional space. This feature vector describes the shape of the gripper. We generate a database of all possible grasps for each object in the feature vector space. Then we use a search algorithm for intersecting all possible grasps over all parts and finding a common grasp suitable for all objects. Each point (feature vector) is the grasp configuration for a group of objects, which implies for the future end-effector design. The final step classifies the objects to grasps found, according to the common points found. The algorithm will be useful for assembly line robots in reducing end-effector design and manufacturing time and final product cost.

This work was supported by General Motors Corp. Ltd.